Introduction

Weld mesh, a fundamental component in construction, agriculture, and manufacturing, plays a pivotal role in shaping the infrastructure we interact with daily. Fence Contractor This versatile material is created by welding wires together, forming a mesh pattern that brings strength and durability to a variety of applications. Fence Contractor Coimbatore In this exploration, we’ll delve into the intricacies of weld mesh, from its basic definition to its widespread applications, highlighting its significance in diverse industries.

What is Weld Mesh?

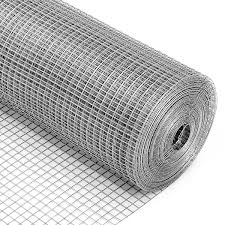

Weld mesh, at its core, is a structured grid formed by welding intersecting wires. Construction Reinforcement Materials The materials used in its construction can vary, with steel, stainless steel, and galvanized steel being among the most common choices. Stainless Steel Wire Grid This welding process not only creates a visually consistent pattern but also enhances the overall strength and resilience of the mesh, making it a preferred material in various construction and manufacturing projects.

Advantages of Weld Mesh

One of the standout features of weld mesh is its inherent strength and durability. Customizable Wire Structures The welding process ensures that the mesh can withstand substantial loads and adverse environmental conditions, making it a reliable choice for projects that demand robust materials. Cost-Effective Mesh Solutions Beyond its physical attributes, weld mesh proves to be a cost-effective solution for various applications. Its longevity and low maintenance contribute to a reduced overall cost of ownership compared to alternative materials and methods.

Tips for Working with Weld Mesh

When working with weld mesh, prioritizing safety is paramount. Versatile Wire Mesh Employers and workers should adhere to proper safety protocols, including the use of protective gear and ensuring adequate ventilation in welding areas. Mesh Welding Techniques Understanding the nuances of welding techniques is crucial for achieving optimal results with weld mesh. Different types of weld mesh may require specific approaches to ensure structural integrity and longevity.

Maintenance

Maintaining weld mesh structures is paramount to ensuring their longevity and sustained functionality. Maintenance Tips for Wire Mesh Regular inspections and proactive care are essential elements of an effective maintenance routine. Durable Mesh Products Begin by checking for any signs of wear, corrosion, or damage to the weld mesh. Addressing minor issues promptly can prevent them from escalating into more significant problems. Custom Mesh Fabrication In environments where corrosion is a concern, such as coastal areas, applying protective coatings or opting for galvanized weld mesh can significantly extend the lifespan of the structure.

Conclusion

In conclusion, weld mesh stands as a testament to the union of strength, versatility, and practicality in construction, agriculture, and manufacturing. Cost-Effective Mesh Solutions Its applications are as diverse as the industries it serves, and its advantages make it an invaluable asset in modern projects. Custom Mesh Fabrication As we navigate the intricate web of weld mesh, understanding its properties and applications becomes a key factor in creating robust and enduring structures.