Introduction

Plastic wire mesh is a unique and adaptable material that has many uses in a variety of industries when it comes to contemporary materials. In contrast to conventional wire meshes composed of metals such as aluminum or stainless steel, plastic wire mesh has special qualities that allow it to be used in a variety of applications where corrosion resistance, flexibility, and durability are critical.

What is a Plastic Wire Mesh?

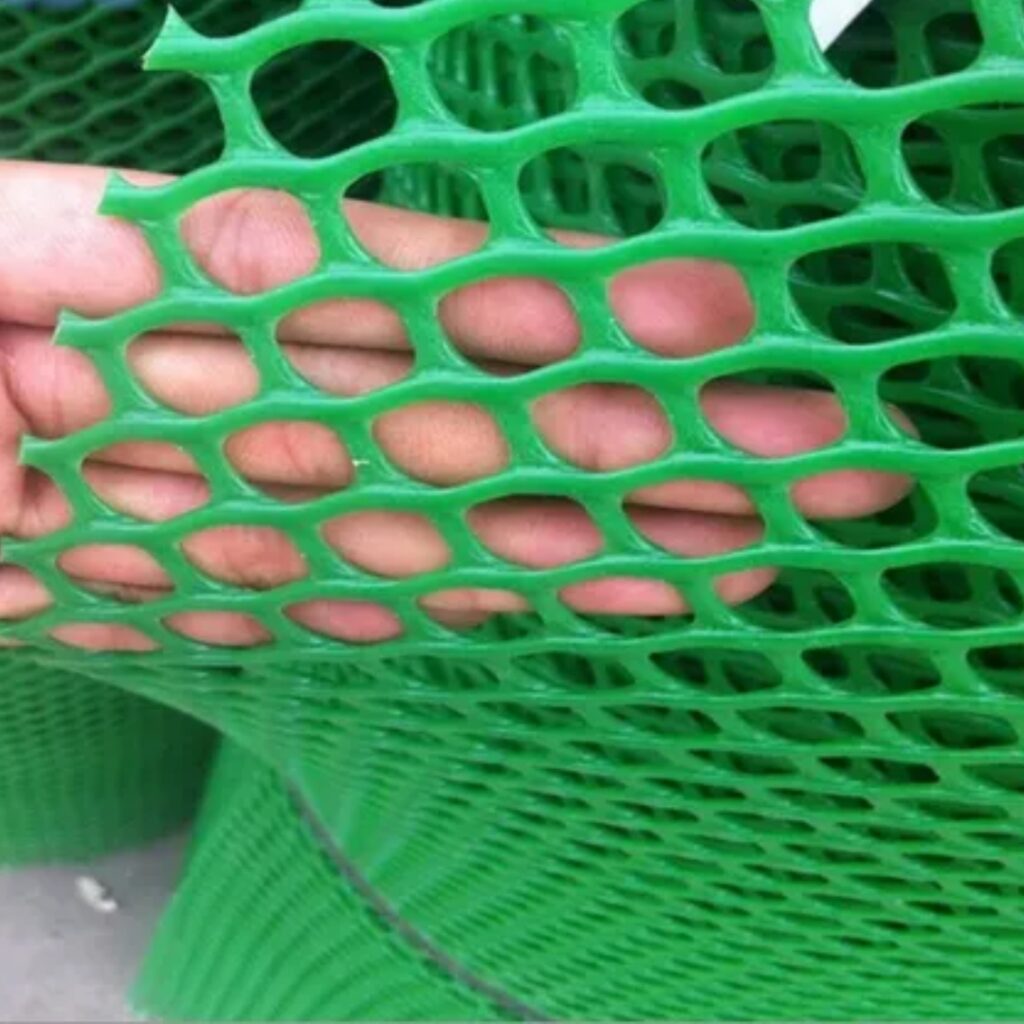

Made of high-density polyethylene (HDPE) or polypropylene (PP), plastic wire mesh is notable for its remarkable resistance to environmental elements like dampness, chemicals, and UV light. By carefully weaving these materials together, a mesh structure that is suited for a given application can be produced. Plastic wire mesh reliably and versatilely performs in a variety of situations, including industrial settings for conveyor belts and filtration, building for reinforcement and erosion control, and agriculture for crop protection and support structures.

1. Uses in Horticulture and Agriculture

Plastic wire mesh is very important in horticulture and agriculture because of its durability and adaptability. It is widely utilized for many different purposes, including crop protection, where it creates barriers around plants to protect them from pests and bad weather while yet allowing for the right amount of sunlight exposure and airflow. In addition to offering a sturdy foundation for development and guarding against harm to fragile stems and fruits, plastic wire mesh is a vital support structure for climbing plants like tomatoes and beans. It is also used in gardening and landscaping to build trellises, fencing, and compost bins, which improves the appearance of gardens and allows for effective waste management. Due to the material’s resilience to UV light, chemicals, and moisture, it is an essential part of contemporary horticulture and guarantees lifespan and dependability.

2. Building and Construction Sectors

3. Applications in Industry and Manufacturing

plastic wire mesh has special qualities, it is used in industry and manufacturing for a wide range of applications. It is widely used in filtration systems, where its robustness and resistance to chemicals make it perfect for separating liquids and solids in a range of industrial operations. Because of its hygienic properties and simplicity of cleaning, plastic wire mesh is also used in conveyor belts, especially in manufacturing and food processing facilities. It is also appropriate for electrical insulation applications due to its non-conductive qualities.

4. Recreational and Environmental Uses

Owing to its versatility and longevity, plastic wire mesh finds beneficial uses in both environmental and recreational situations. It is used in aquaculture to build cages and nets that maximize environmental impact reduction and offer safe habitats for fish farming. Plastic wire mesh is used in fencing and compost bins for gardening and landscaping, which helps to neaten up outdoor areas and manage trash effectively. By aiding in the prevention of erosion and stabilizing soil in delicate environments, it also plays a significant part in environmental conservation.

Conclusion

Plastic wire mesh is a material that is always innovating and adapting to meet the needs of many industries. It provides solutions that combine environmental sustainability, flexibility, and durability. Its adaptable qualities make it an essential material for many real-world applications, whether in manufacturing, building, agricultural, or environmental applications. Plastic wire mesh is prepared to meet the demands of a changing world as technology develops and environmental concerns increase. It offers dependable and effective solutions wherever it is used.