Introduction

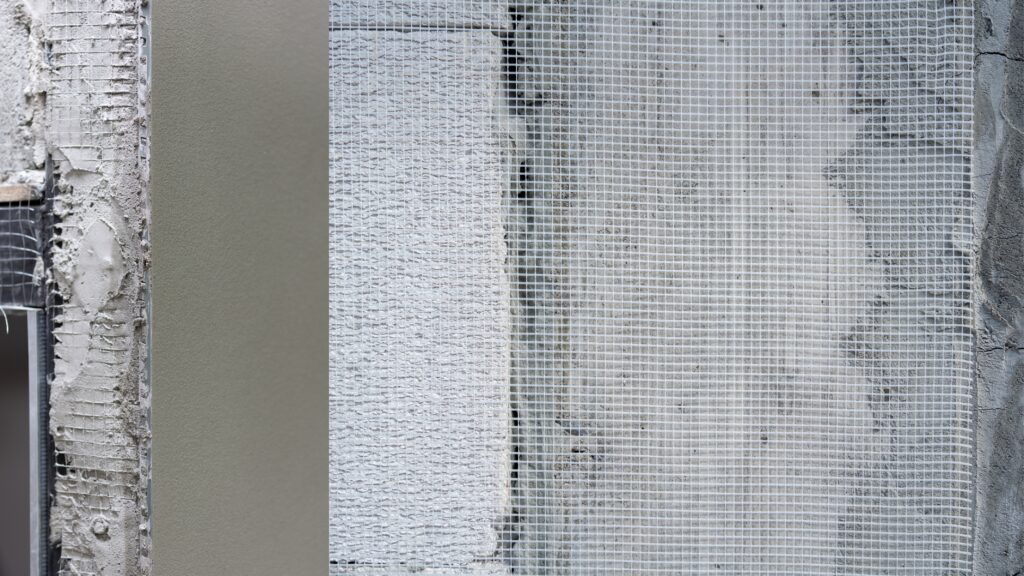

Plastering with chicken mesh, also known as wire mesh, is a typical technique in construction to increase the strength and endurance of the plasterwork, particularly on surfaces that require more reinforcement or are prone to cracking. This is the purpose and application of chicken mesh in plastering. Reinforcing made of chicken mesh serves to evenly distribute loads across the surface, lowering the chance of cracking. It can aid in the plaster’s adhesion to the wall and aid in preventing cracks.

Why Use Chicken Mesh in Plastering?

Prevents Cracks: By distributing plaster uniformly and offering a flexible base that can absorb minute movements in the underlying surface, chicken mesh helps prevent cracks.

Enhances Adhesion: Especially on smooth or challenging surfaces like concrete, bricks, or drywall, the mesh serves as a key, or a gripping surface, for the plaster to stick to.

Strengthens Plaster: By strengthening the plaster, the wall becomes more durable overall and more resistant to damage and impact.

Bridges Gaps & Joins: To provide a consistent surface for plastering, chicken mesh is perfect for bridging gaps or joins between various materials (such as wood and concrete).

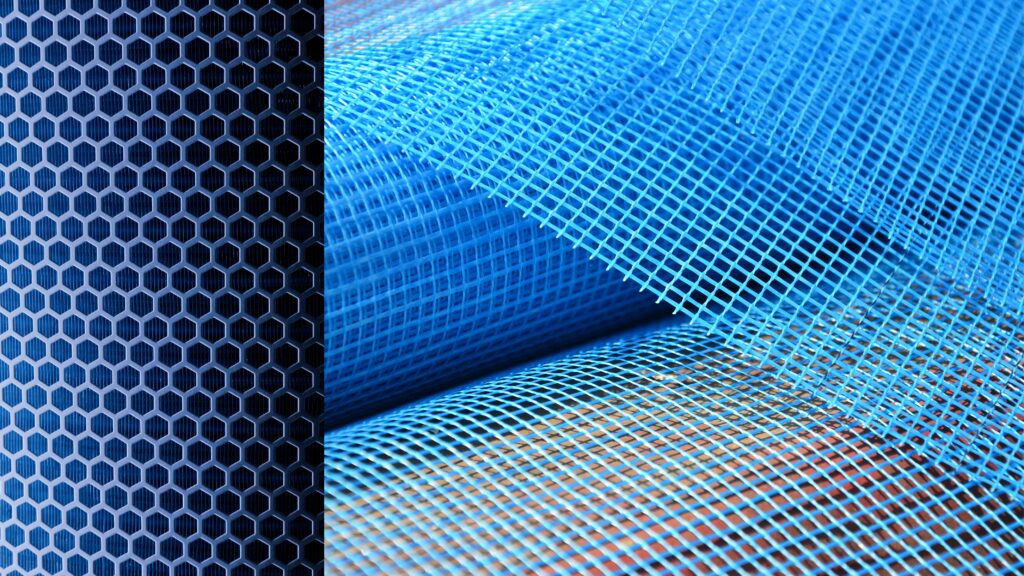

Types of Chicken Mesh for Plastering

The most popular kind of steel mesh for plastering is galvanized, which helps to prevent rust and corrosion over time.

Stainless steel mesh is a more costly but extremely resilient material that is frequently used in damp environments, including outdoor walls or bathrooms.

How to Plaster Using Chicken Mesh:

Some Important steps that include chicken mesh by plastering , Surface Readiness , Scale the Mesh to Fit , Connect the Mesh to the Surface , Put the plaster on by completing . A form of wire mesh used in building is called chicken mesh, and it serves as a reinforcing element for walls made of stucco or plaster. It is constructed of galvanized steel wire, much like the chicken mesh used in poultry farming, and is woven into a grid pattern with tiny gaps.

Advice on Plastering Using Chicken Mesh

Choose the Correct Gauge: Medium-gauge (18 to 20) mesh works well for most plastering applications, while thicker mesh (lower gauge) offers superior reinforcement.

Make Sure There’s Good Coverage: To prevent weak points, always overlap mesh at joints.

Prevent Rust: To maintain longevity, particularly in moist or humid locations, choose galvanized or rust-resistant mesh.

Stretch the Mesh: To prevent bulges that could cause the plaster application to be uneven, keep the mesh taut during installation.

Chicken mesh applications in plastering

The strength and longevity of the plaster coat are improved by using chicken mesh. It is also employed to stop wall fractures from forming. A number of factors, including the impact of seasonal variations, shrinkage cracks, shoddy building techniques, etc., can cause cracks. Plaster of Paris, another name for gypsum plastering, is a common material for interior surfaces. A naturally occurring mineral called gypsum creates a smooth paste that dries rapidly and gives surfaces a polished, clean look when combined with water.

Conclusion

When plastering, using chicken mesh is a good way to support the plaster, keep it from cracking, and guarantee a smooth, long-lasting finish. Your plastering job will endure longer and be stronger if you include this phase, especially on unstable or mixed-material surfaces. This mesh is used to stabilize interior wall surfaces and lessen the likelihood of cracks resulting from substrate flaws, drying plaster (spider web cracks), excessive stress from window and partition regions, and home shifting.